NDE for AM

Motivation

Additive manufacturing offers a paradigm shift in engineering as previous design constraints, such as tooling paths in matching are removed. The ability to create novel free form structures, such as lattices, clearly offers vast potential benefits for high performance industries including aerospace, medical and tooling. However, the uptake of AM components has been hindered as the process are prone to a variety of defects, such as porosity and cracking, which due to the variation in length scales, 10 µm to 500 µm, and the number of processing parameters, >150, make predicting and optimising against these defects near-impossible.

As such, our optics group is currently working on a number of ways to perform non-destructive evaluation on additive manufactured (AM) parts; currently, XCT is widely used in industry for part validation but is a strictly post-process ex-situ technique and has both time and safety implications. Our aim is to take advantage of the layer-by-layer nature of the AM process to inspect during the build to create a volumetric dataset and validate the part in real-time. Further to real-time validation of the component in-situ inspection offers opportunities to adjust build parameters during the build based on processing signal, analogous with the closed-loop feedback used in conventional machining. Alongside the management of components defects in AM significant research in the field is also dedicated to understanding the microstructure and subsequent mechanical properties of the AM components; in future it is envisaged that the processes can be adapted as such to tailor the component microstructure for a given role, as such a technique which can both verify a components integrity and interrogate the microstructure will be well placed to meet the demands, both current and future, of the AM industry,

SRAS on Additive Manufacturing

Our existing laser ultrasound technique SRAS has previously been used to image the microstructure of metallic samples, giving both grain size and orientation, making it an interesting tool for investigation of SLM samples. Furthermore, In addition to this useful information, the loss of signal or a drastic change in signal amplitude/frequency can be used to measure the presence of both defects on the surface and in the near-surface region. These capabilities combined with the fact SRAS is a non-contact, non-destructive technique makes it an ideal candidate for AM components.

The first SRAS data from AM samples were obtained using the O-SAM system in 2011. The two figures below illustrate the SAW velocity across a blown powder and wire deposited samples with the SAW propagating in the direction of the white arrows. These initial data sets paved the way for the following generations of SRAS system to further investigate the capabilities of SRAS as an NDE tool for AM.

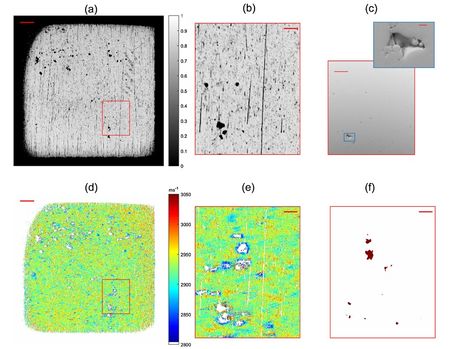

In 2016 a more modern SRAS system was used on Selective Laser Melting (SLM) samples. This system demonstrated a relationship between the mean SAW velocity and laser power used to build eleven cubes using Ti64 powder. As the laser was power increased, an increase in the mean SAW velocity was measured. It was also shown how an in-process SRAS inspection could provide closed-loop feedback to improve the SLM process as a whole. When specifically considering pores, it was shown that alongside detecting, counting and sizing the surface pores, the system was also able to detect subsurface pores. This was in the form of a drastic change in the SAW velocity by ~300 ms-1, wherein the thin plate-like region above the pores, the SAW transformed into a Lamb wave.

Average acoustic amplitude and velocity data presented for each SLM specimen. The velocity decreases with build power and is not dependant on the acoustic amplitude as the 190 W and 200 W samples had similar acoustic amplitude to the lower power samples, yet their velocity was as expected for well-consolidated material. |

Images for the 190 W AM test sample (a) Optical image (scale bar 1 mm) (b) Optical zoom (scale bar 250 um), (c) SEM micrograph of the corresponding area (scale bar 250 um) and inset zoom of large pore (scale bar 25 um). (d) Acoustic velocity map (scale bar 1 mm) (e) zoom of acoustic data (scale bar 250 ?m) (f) XCT subsurface (with no surface) data of zoomed region up to an approximate depth of 60 ?m (scale bar 250 um) |

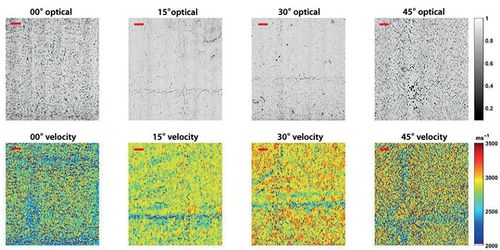

The next set of experiments carried out in 2017 were aimed at understanding the capability of SRAS to detect changes to build process, specifically the scan strategies used. Four 10mm cubes were manufactured using a nickel superalloy power (CM247LC) on a Realizer SLM machine. The cubes were made up of four small 5 mm square islands. One sample was used as a control (0°) and the islands were rotated on the other three samples relative to the previous layer. The rotation angles were set to 15°, 30° and 45° across the tree samples. Using SRAS data and verified by optical microscopy several trends were identified between the crack and pore distribution relative to the island rotation angle. Furthermore, the island boundaries were identified using SRAS based on their distinctly different drop in the group SAW velocity.

Plan view of the overall scan strategy for a 30° sample. The region in which the scan lines overshoot the assigned island is highlighted with green arrows alongside both SRAS optical and velocity maps of the same region. Outlined in black, the optical image shows no indication of the scan lines, whereas the velocity map clearly illustrates a change in this region. |

Some further work was carried out towards understanding the data obtained using SRAS from form AM samples. In this case, both the cross-section and sidewall of Wire–arc additive manufacturing (WAAM) samples were inspected using SRAS. Here we are able to identify the differences between undeformed and rolled samples.

By incorporating the SRAS instrument into the SLM build machine, it shall be possible to image 3D renders both defects and the microstructure on a layer-by-layer basis. The challenges in this project are both in the optical setup, such as measuring signals off rough surfaces, as well as mechanical integration, where atmosphere, temperature, small envelope and interfering particles are all factors to overcome. Furthermore, for the technology to be commercially applicable the quality of data must be balanced against the impact on the manufacturing time. In order to assess this, we have developed a framework for comparing the spatial capability and temporal penalty of various inspection systems.

Research Team

Adam Clare, Matt Clark, Richard Smith, Wenqi Li, Rikesh Patel, Rafael Fuentes Dominguez, Don Pieris and Paul Dryburgh are actively working on this project. Previous contributors include Steve Sharples, Matthias Hirsch and Samuel Osei Achamfuo-Yeboah.

Related Publications and Talks

Publications

R. J. Smith, M. Hirsch, P. Patel, W. Li, A. T. Clare, S. D. Sharples - Spatially resolved acoustic spectroscopy for selective laser melting- Journal of Materials Processing Technology 236:93--102,2016

- https://www.sciencedirect.com/science/article/pii/S0924013616301352

BibtexAuthor : R. J. Smith, M. Hirsch, P. Patel, W. Li, A. T. Clare, S. D. Sharples

Title : Spatially resolved acoustic spectroscopy for selective laser melting

In : Journal of Materials Processing Technology -

Address :

Date : 2016

M. Hirsch, R. Patel, W. Li, G. Guan, R. K. Leach, S. D. Sharples, A. T. Clare - Assessing the capability of in-situ nondestructive analysis during layer based additive manufacture

- Additive Manufacturing 13:135--142,2017

- https://www.sciencedirect.com/science/article/pii/S2214860416301877

BibtexAuthor : M. Hirsch, R. Patel, W. Li, G. Guan, R. K. Leach, S. D. Sharples, A. T. Clare

Title : Assessing the capability of in-situ nondestructive analysis during layer based additive manufacture

In : Additive Manufacturing -

Address :

Date : 2017

M. Hirsch, S. Catchpole-Smith, R. Patel, P. Marrow, W. Li, C. Tuck, S. D. Sharples, A. T. Clare - Meso-scale defect evaluation of selective laser melting using spatially resolved acoustic spectroscopy

- Proc. R. Soc. A 473(2205):170--194,2017

- http://rspa.royalsocietypublishing.org/content/473/2205/20170194

BibtexAuthor : M. Hirsch, S. Catchpole-Smith, R. Patel, P. Marrow, W. Li, C. Tuck, S. D. Sharples, A. T. Clare

Title : Meso-scale defect evaluation of selective laser melting using spatially resolved acoustic spectroscopy

In : Proc. R. Soc. A -

Address :

Date : 2017

M. Hirsch, P. Dryburgh, R. Patel, S. Catchpole-Smith, L. Perry, S. D. Sharples, I. A. Ashcroft, A. T. Clare - Targeted rework strategies for powder bed additive manufacture

- Additive Manufacturing 19:127-133,2018

- https://www.sciencedirect.com/science/article/pii/S2214860417303925

BibtexAuthor : M. Hirsch, P. Dryburgh, R. Patel, S. Catchpole-Smith, L. Perry, S. D. Sharples, I. A. Ashcroft, A. T. Clare

Title : Targeted rework strategies for powder bed additive manufacture

In : Additive Manufacturing -

Address :

Date : 2018

R. Patel, M. Hirsch, P. Dryburgh, D. Pieris, S. Achamfuo-Yeboah, R. Smith, R. Light, S.D. Sharples, A.T. Clare, Matt Clark - Imaging Material Texture of As-Deposited Selective Laser Melted Parts Using Spatially Resolved Acoustic Spectroscopy

- Applied Sciences 8(10):1991,2018

- https://www.mdpi.com/2076-3417/8/10/1991

BibtexAuthor : R. Patel, M. Hirsch, P. Dryburgh, D. Pieris, S. Achamfuo-Yeboah, R. Smith, R. Light, S.D. Sharples, A.T. Clare, Matt Clark

Title : Imaging Material Texture of As-Deposited Selective Laser Melted Parts Using Spatially Resolved Acoustic Spectroscopy

In : Applied Sciences -

Address :

Date : 2018

D. Pieris, R. Patel, P. Dryburgh, M. Hirsch, W. Li, S. Sharples, R.J. Smith, A.T. Clare, M. Clark - Spatially resolved acoustic spectroscopy towards online inspection of additive manufacturing

- Insight - Non-Destructive Testing & Condition Monitoring 61(3):132-137,2019

- BibtexAuthor : D. Pieris, R. Patel, P. Dryburgh, M. Hirsch, W. Li, S. Sharples, R.J. Smith, A.T. Clare, M. Clark

Title : Spatially resolved acoustic spectroscopy towards online inspection of additive manufacturing

In : Insight - Non-Destructive Testing & Condition Monitoring -

Address :

Date : 2019

P. Dryburgh, D. Pieris, F.Martina, R. Patel, S. Sharples, W. Li, A.T. Clare, S. Williams, R.J. Smith - Spatially Resolved Acoustic Spectroscopy for Integrity Assessment in Wire-Arc Additive Manufacturing

- Additive Manufacturing accepted,2019

- BibtexAuthor : P. Dryburgh, D. Pieris, F.Martina, R. Patel, S. Sharples, W. Li, A.T. Clare, S. Williams, R.J. Smith

Title : Spatially Resolved Acoustic Spectroscopy for Integrity Assessment in Wire-Arc Additive Manufacturing

In : Additive Manufacturing -

Address :

Date : 2019

Conference Papers

S. D. Sharples, R. A. Light, S. O. Achamfuo-Yeboah, M. Clark, M. G. Somekh - The SKED: Speckle Knife Edge Detector

- 3rd International Symposium on Laser-Ultrasonics and Advanced Sensing, Yokohama, Japan 581,2013

- http://iopscience.iop.org/article/10.1088/1742-6596/520/1/012004

BibtexAuthor : S. D. Sharples, R. A. Light, S. O. Achamfuo-Yeboah, M. Clark, M. G. Somekh

Title : The SKED: Speckle Knife Edge Detector

In : 3rd International Symposium on Laser-Ultrasonics and Advanced Sensing, Yokohama, Japan -

Address :

Date : 2013

S. O. Achamfuo-Yeboah, R. A. Light, S. D Sharples - Optical detection of ultrasound from optically rough surfaces using a custom CMOS sensor

- 13th Anglo-French Physical Acoustics Conference (AFPAC2014) 581,2014

- http://iopscience.iop.org/article/10.1088/1742-6596/581/1/012009/meta

BibtexAuthor : S. O. Achamfuo-Yeboah, R. A. Light, S. D Sharples

Title : Optical detection of ultrasound from optically rough surfaces using a custom CMOS sensor

In : 13th Anglo-French Physical Acoustics Conference (AFPAC2014) -

Address :

Date : 2014

P. Dryburgh, R. Patel, S. Catchpole-Smith, M. Hirsch, L. Perry, R. J. Smith, M. Clark, I. A. Ashcroft, A. T. Clare - Targeted rework of powder bed fusion additive manufacturing

- Proceedings of LPM2018 - the 19th International Symposium on Laser Precision Microfabrication ,2018

- https://nottingham-repository.worktribe.com/output/1190715/targeted-rework-of-powder-bed-fusion-additive-manufacturing

BibtexAuthor : P. Dryburgh, R. Patel, S. Catchpole-Smith, M. Hirsch, L. Perry, R. J. Smith, M. Clark, I. A. Ashcroft, A. T. Clare

Title : Targeted rework of powder bed fusion additive manufacturing

In : Proceedings of LPM2018 - the 19th International Symposium on Laser Precision Microfabrication -

Address :

Date : 2018

D. M.Pieris, R. Patel, P. Dryburgh, M. Hirsch, W. Li, S. D. Sharples, R. J. Smith, A. T. Clare, M. Clark - Spatially resolved acoustic spectroscopy additive manufacturing: towards online inspection

- Proceedings of BINDT2018 - the 57th Annual British Conference on Non-Destructive Testing ,2018

- https://nottingham-repository.worktribe.com/output/1191130/spatially-resolved-acoustic-spectroscopy-additive-manufacturing-towards-online-inspection

BibtexAuthor : D. M.Pieris, R. Patel, P. Dryburgh, M. Hirsch, W. Li, S. D. Sharples, R. J. Smith, A. T. Clare, M. Clark

Title : Spatially resolved acoustic spectroscopy additive manufacturing: towards online inspection

In : Proceedings of BINDT2018 - the 57th Annual British Conference on Non-Destructive Testing -

Address :

Date : 2018

- 15th Anglo-French Physical Acoustics Conference, Fréjus, France ,2015

- BibtexAuthor : Patel Rikesh, Guan Guanying, Hirsch Matthias, Li Wenqi, Smith Richard J., Achamfuo-Yeboah Samual, Light Roger A., Clare Adam T., Tuck Chris, Clark Matt, Sharples Steve D.

Title : On using laser ultrasonic non-destructive evaluation for additive manufactured samples

In : 15th Anglo-French Physical Acoustics Conference, Fréjus, France -

Address :

Date : 2015

Clare Adam T., Sharples Steve D., Tuck Chris, Groom Kristian, Hirsch Matthias, Patel Rikesh, Li Wenqi, Smith Richard J., Guan Guanying - In-Process monitoring of Additive Layer Manufacturing

- 54th Annual Conference of The British Institute of Non-Destructive Testing, Telford, UK ,2015

- BibtexAuthor : Clare Adam T., Sharples Steve D., Tuck Chris, Groom Kristian, Hirsch Matthias, Patel Rikesh, Li Wenqi, Smith Richard J., Guan Guanying

Title : In-Process monitoring of Additive Layer Manufacturing

In : 54th Annual Conference of The British Institute of Non-Destructive Testing, Telford, UK -

Address :

Date : 2015

Patel Rikesh, Hirsch Matthias, Li Wenqi, Smith Richard J., Achamfuo-Yeboah Samual, Tuck Chris, Clark Matt, Clare Adam T., Sharples Steve D. - On using laser ultrasonic non-destructive evaluation for additive manufactured samples

- 4th International Symposium on Laser-Ultrasonics and Advanced Sensing, Illinois, USA ,2015

- BibtexAuthor : Patel Rikesh, Hirsch Matthias, Li Wenqi, Smith Richard J., Achamfuo-Yeboah Samual, Tuck Chris, Clark Matt, Clare Adam T., Sharples Steve D.

Title : On using laser ultrasonic non-destructive evaluation for additive manufactured samples

In : 4th International Symposium on Laser-Ultrasonics and Advanced Sensing, Illinois, USA -

Address :

Date : 2015

Patel Rikesh, Hirsch Matthias, Li Wenqi, Smith Richard J., Achamfuo-Yeboah Samual, Tuck Chris, Clark Matt, Clare Adam T., Sharples Steve D. - On using laser ultrasonic non-destructive evaluation for additive manufactured samples

- 42nd Annual Review of Progress in Quantitative Nondestructive Evaluation Conference, Minneapolis, USA ,2015

- BibtexAuthor : Patel Rikesh, Hirsch Matthias, Li Wenqi, Smith Richard J., Achamfuo-Yeboah Samual, Tuck Chris, Clark Matt, Clare Adam T., Sharples Steve D.

Title : On using laser ultrasonic non-destructive evaluation for additive manufactured samples

In : 42nd Annual Review of Progress in Quantitative Nondestructive Evaluation Conference, Minneapolis, USA -

Address :

Date : 2015

Patel Rikesh, Hirsch Matthias, Smith Richard J., Achamfuo-Yeboah Samual, Clare Adam T., Sharples Steve D. - Laser ultrasonic inspection of as-deposited AM samples

- 5th International Symposium on Laser-Ultrasonics and Advanced Sensing, Linz, Austria ,2016

- BibtexAuthor : Patel Rikesh, Hirsch Matthias, Smith Richard J., Achamfuo-Yeboah Samual, Clare Adam T., Sharples Steve D.

Title : Laser ultrasonic inspection of as-deposited AM samples

In : 5th International Symposium on Laser-Ultrasonics and Advanced Sensing, Linz, Austria -

Address :

Date : 2016

Clare Adam T., Sharples Steve D., Leach Richard K., Guan Guanying, Hirsch Matthias, Patel Rikesh - In-Process monitoring of Additive Layer Manufacturing

- 66th CIRP General Assembly, Guimarães, Portugal ,2016

- BibtexAuthor : Clare Adam T., Sharples Steve D., Leach Richard K., Guan Guanying, Hirsch Matthias, Patel Rikesh

Title : In-Process monitoring of Additive Layer Manufacturing

In : 66th CIRP General Assembly, Guimarães, Portugal -

Address :

Date : 2016

Clare Adam T., Hirsch Matthias, Guan Guanying, Patel Rikesh, Li Wenqi, Dryburgh Paul, Milesh Pieris Don, Sharples Steve D. - Approaches for AM in-process inspection using SRAS and OCT

- EUSPEN Special Interest Group Meeting: Quality Control for Additive Manufacturing, Coventry, UK ,2017

- BibtexAuthor : Clare Adam T., Hirsch Matthias, Guan Guanying, Patel Rikesh, Li Wenqi, Dryburgh Paul, Milesh Pieris Don, Sharples Steve D.

Title : Approaches for AM in-process inspection using SRAS and OCT

In : EUSPEN Special Interest Group Meeting: Quality Control for Additive Manufacturing, Coventry, UK -

Address :

Date : 2017

Pieris Don M., Catchpole-Smith Sam, Patel Rikesh, Hirsch Matthias, Dryburgh Paul, Li Wenqi, Sharples Steve D., Smith Richard, Clare Adam T., Clark Matt - Detection and Manipulation of AM Component Microstructure using SRAS

- Institute of Physics: Optics and Ultrasound IV, University of Strathclyde, UK ,2017

- BibtexAuthor : Pieris Don M., Catchpole-Smith Sam, Patel Rikesh, Hirsch Matthias, Dryburgh Paul, Li Wenqi, Sharples Steve D., Smith Richard, Clare Adam T., Clark Matt

Title : Detection and Manipulation of AM Component Microstructure using SRAS

In : Institute of Physics: Optics and Ultrasound IV, University of Strathclyde, UK -

Address :

Date : 2017

Clare Adam T., Dryburgh Paul, Pieris Don M., Patel Rikesh, and Li Wenqi, Smith Richard, Clark Matt - Finding and Fixing Defects in Metal Powder Bed Systems

- Manufacture using Advanced Powder Processes: 1st International Conference ,2018

- BibtexAuthor : Clare Adam T., Dryburgh Paul, Pieris Don M., Patel Rikesh, and Li Wenqi, Smith Richard, Clark Matt

Title : Finding and Fixing Defects in Metal Powder Bed Systems

In : Manufacture using Advanced Powder Processes: 1st International Conference -

Address :

Date : 2018